Conveyor Belts

Product Overview

General Purpose Conveyor Belts

General Purpose Conveyor Belts are specifically designed to withstand high levels of wear and abrasion. The general-purpose range includes three specific grades — M-24, N-17, and SAR.

The SAR grade is specially recommended for use in port handling facilities and iron ore mines due to its superior resistance to abrasion and harsh working conditions. The abrasion tests for the belt covers are conducted in accordance with DIN 53516 standards.

Special wear-resistant covers with lower abrasion loss can also be formulated by ARB Conveyors Limited on request to meet customized application requirements.

.jpg)

Heat Resistant Conveyor Belts

Heat Resistant Conveyor Belts are manufactured by ARB Conveyors Limited in various grades to suit specific application requirements. ARBCL Heat Resistant Belts are widely accepted in steel plants (for handling sinter and coke) and cement plants (for handling clinker), among other industries.

As a rule, special heat-resistant belts are required for transporting materials with temperatures exceeding 70°C. Typical materials include sinter, cement, moulding sand, coke, and similar substances.

Service Life Considens

The service life of these belts depends not only on the temperature of the material and the belt construction but also on several other factors such as:

- Properties of the material being conveyed

- Drop height during loading

- Material size and density

- Length and speed of the conveyor

- Possible chemical interactions

It is highly recommended to have technical discussions with ARBCL during the pre-ordering stage to ensure the selection of the most suitable belt cover and construction for the specific installation.

Aramid Conveyor Belts

Aramid Conveyor Belts are made with aromatic polyamide (aramid) as the carcass material, providing exceptionally high tensile strength and very low elongation.

These lightweight belts help reduce the overall power consumption of the conveyor system. Even greater energy savings can be achieved when combined with energy-efficient rubber compounds featuring low rolling resistance on the pulley side.

Key Features

- High impact resistance

- Low energy consumption

- Excellent anti-corrosion properties

- Superior tensile strength with minimal stretch

- Lightweight for efficient open

CFW CONVEYOR BELTS

Crows Foot Weave (CFW) Rubber Conveyor Belts are specially designed for high-abuse and heavy-duty applications. These belts are manufactured with a unique EP (polyester–nylon) carcass that delivers superior strength and durability under demanding conditions.

The CFW construction features:

- 50% more warp threads (ends)

- 40% heavier weft yarn

- 20% more weft threads (picks)

- Over twice the strength in the weft direction

This innovative structure provides a belt with up to five times the strength of conventional fabric conveyor belts.

Recommended Applications:

- Rock mining

- Quarrying opens

- Mobile or fixed plant crushing

- Other high-impact, heavy-duty service environments

Key Features:

- Exceptional tensile strength

- Low elongation for stable performance

- Superior rip and tear resistance

- High abrasion resistance

- Excellent cut and gouge resistance

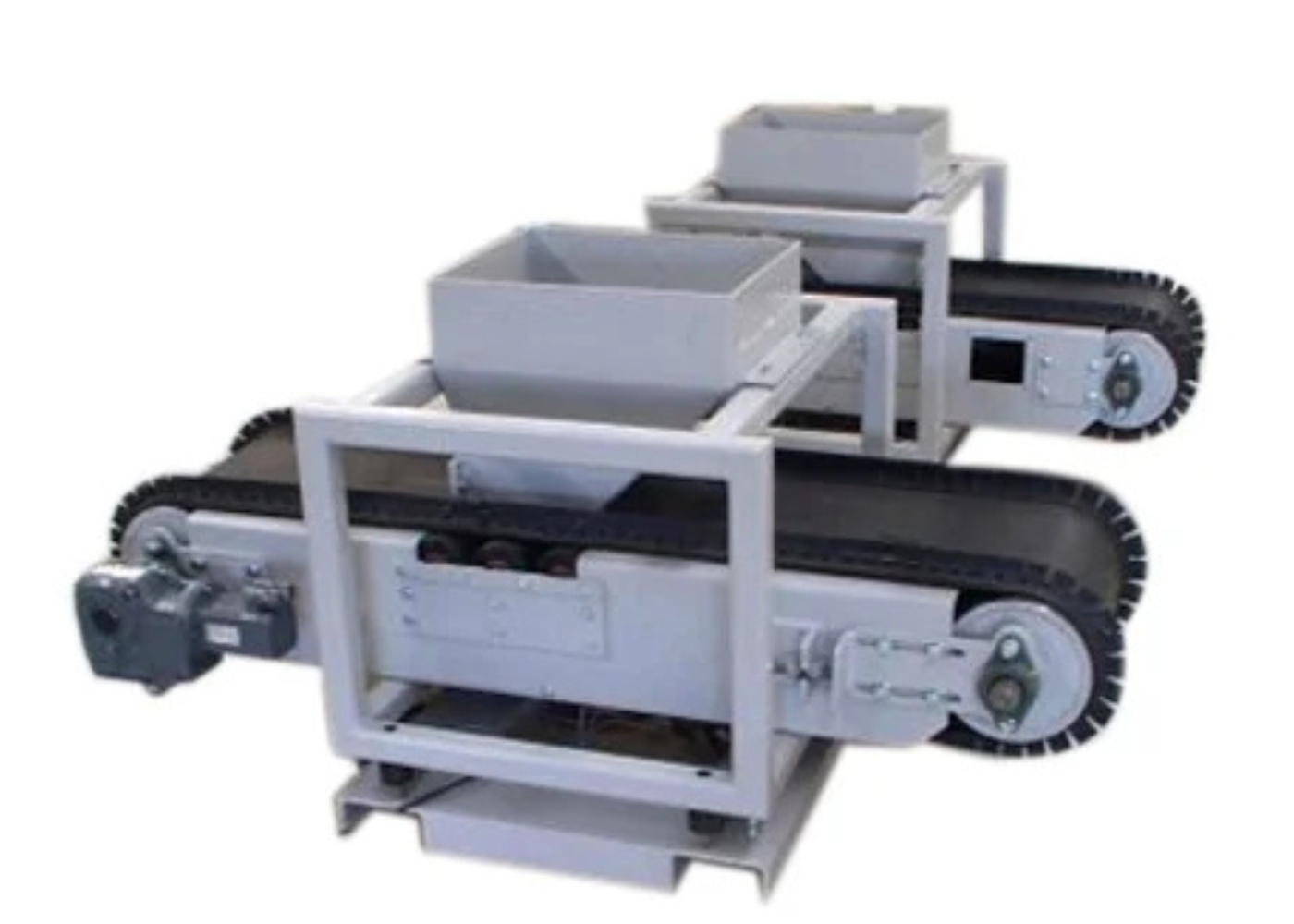

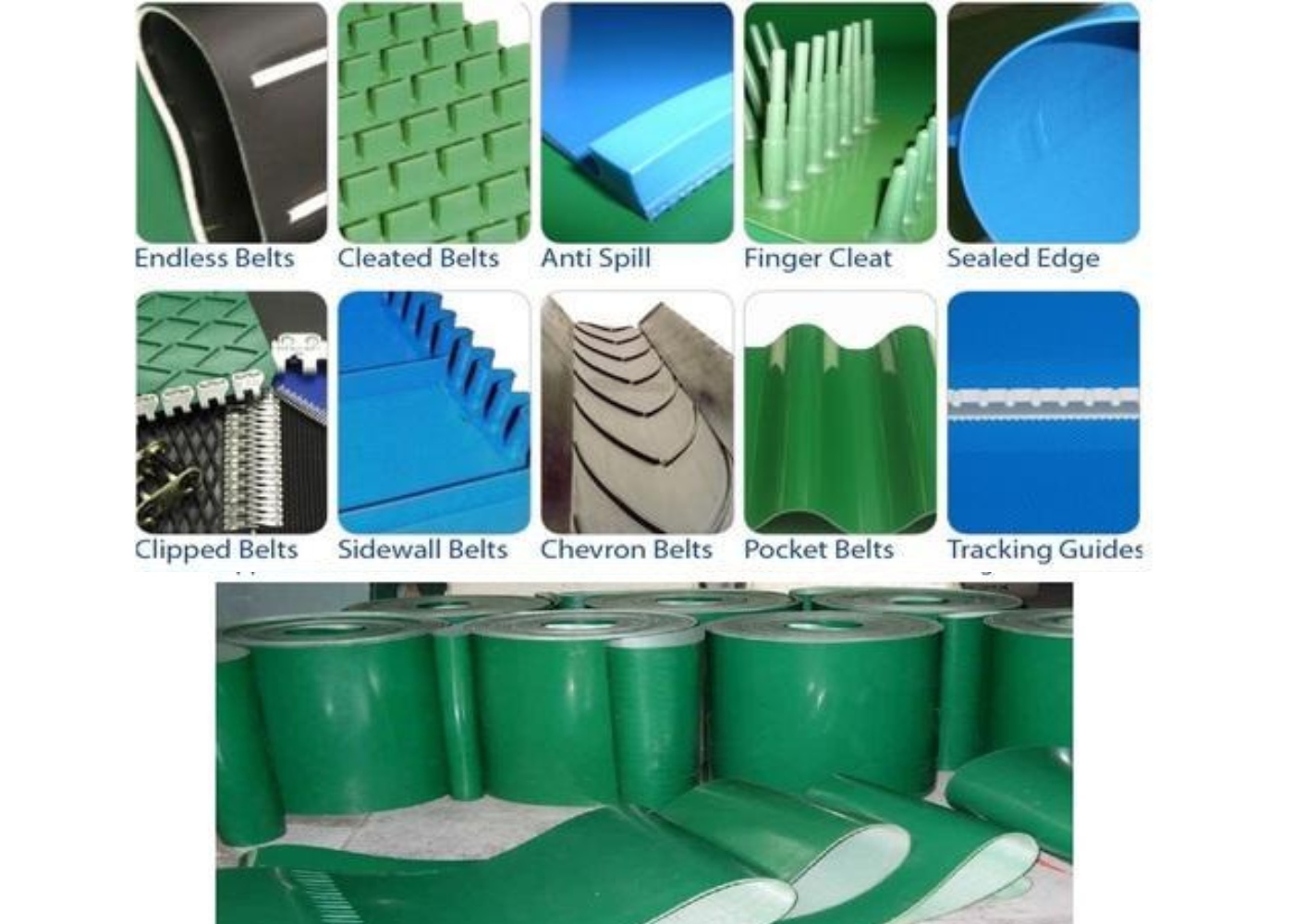

Feeder Belts

Feeder Belts are generally manufactured using 2-ply or 3-ply conveyor belt construction. The standard thickness (top and bottom covers) and other belt specifications can be customized according to specific application requirements.

Most feeder belts are designed to run flat, ensuring smooth material feeding. Flanges or sidewalls can be incorporated to prevent material spillage and can be manufactured as per the customer’s requirements.

Magnetic Separator Belts

Magnetic Separator Belts are custom-manufactured to meet your system’s specific length, width, and cleat requirements. The cleats are hot-vulcanized to the base belt, ensuring a strong bond across the full width and making them an integral part of the belt’s top cover.

For optimal performance, the cleats are inset from each side of the belt to maintain proper tracking and prevent interference with the system’s structure.

Side Wall Belting

We offer a wide range of corrugated sidewalls designed for high-performance conveying applications. All sidewalls are impregnated with a specially woven fabric ply, providing exceptional strength, flexibility, and durability.

The cleats are hot-molded to the base belt, creating a rugged, permanent bond that ensures long-lasting performance under heavy-duty conditions.

Base Belt Construction

The base belt incorporates a cross-stabilizing monofilament ply along with a steel breaker ply for enhanced strength and extended service life in demanding applications.

Cleat Types

- C

- TC

- TC+

- ST

Dimensions:

- Cleat Heights: 50 mm to 210 mm

- Sidewall Heights: 40 mm to 200 mm

Conveyor Fasteners

Chevron Conveyor Belts

PVC and Rubber Food Grade Conveyor Belts

PVC and PU Conveyor Belts

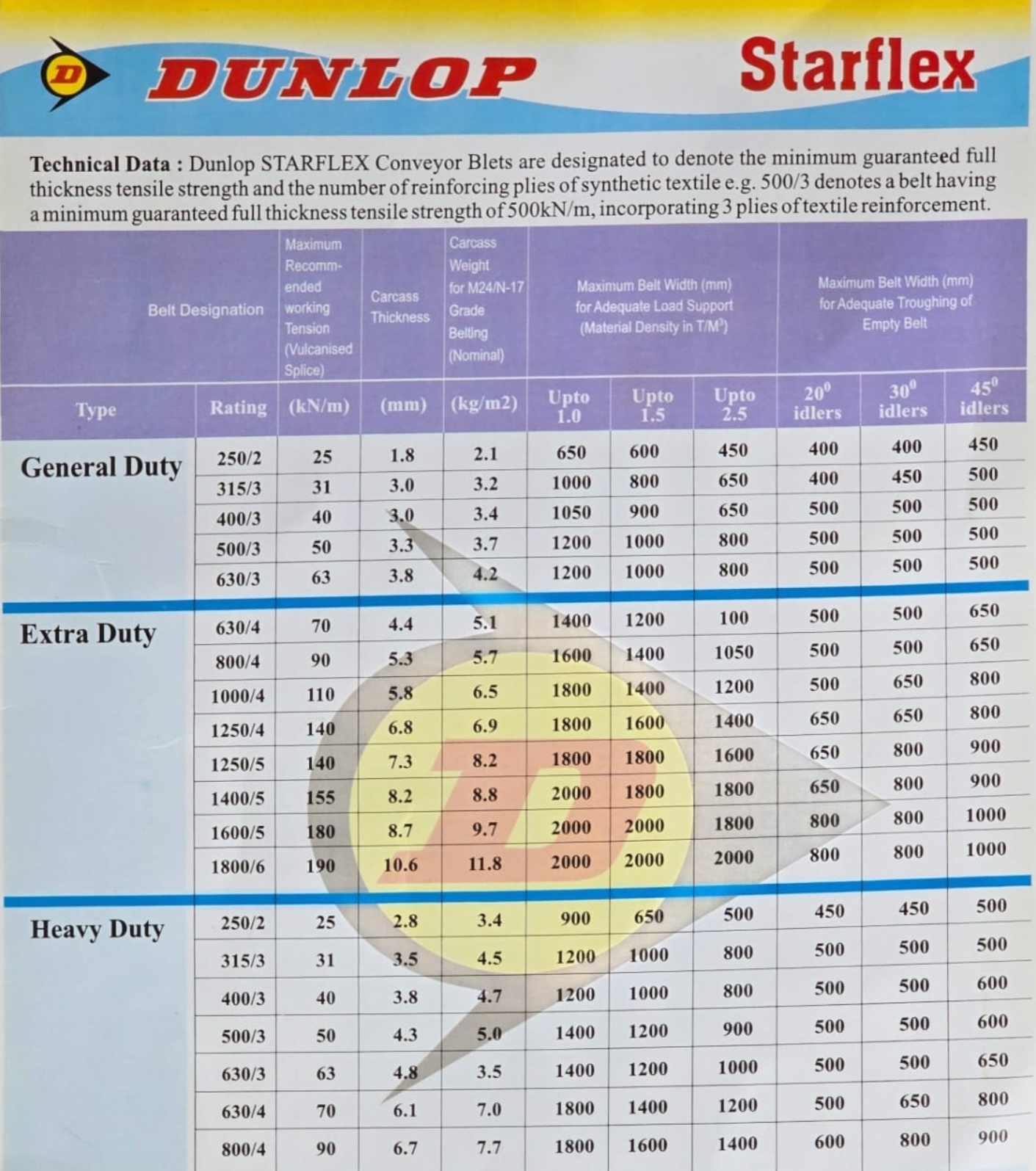

DUNLOP STARFLEX CONVEYOR BELTS

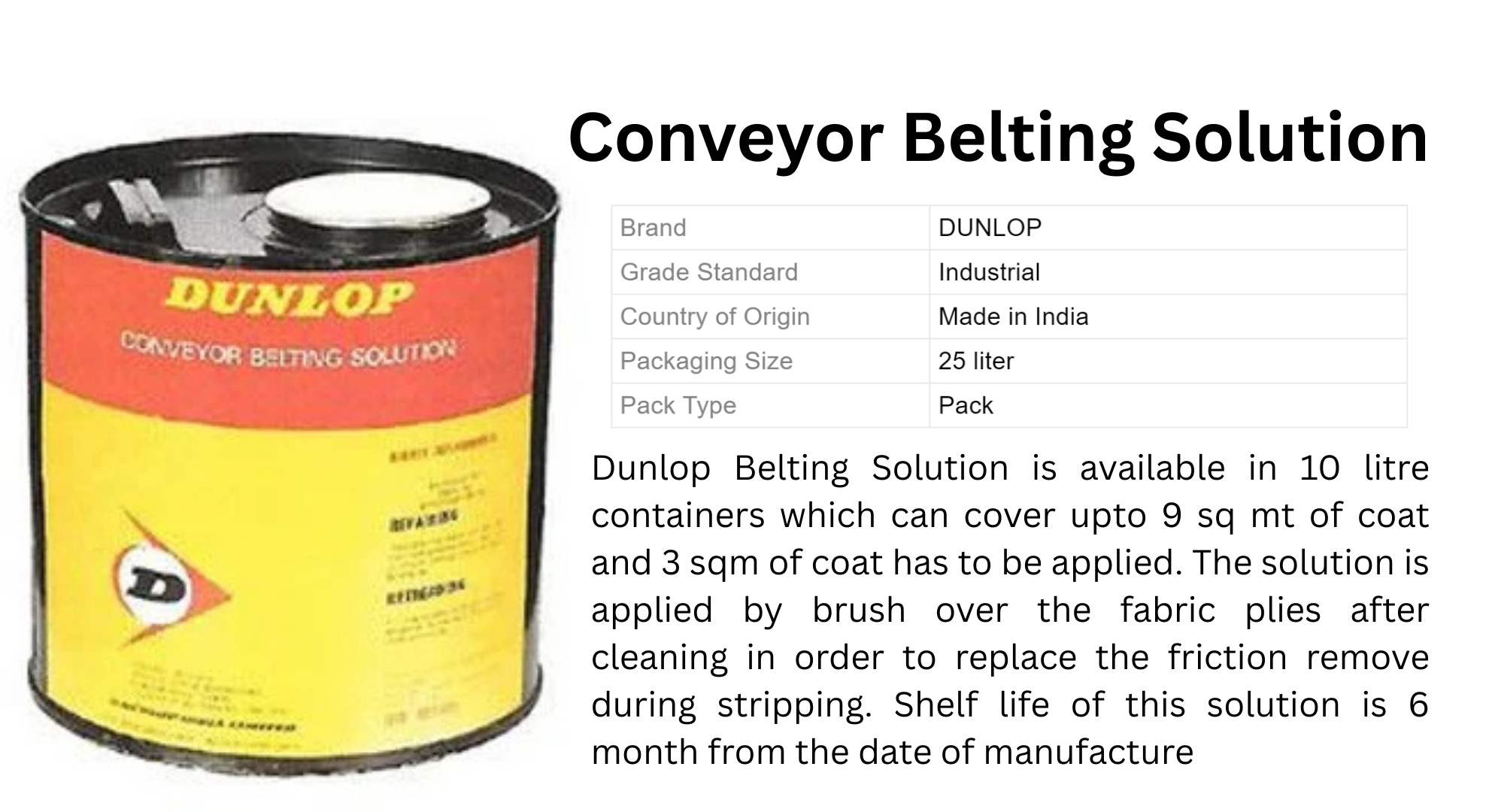

Conveyor Repair Materials

As a prominent and leading wholesaler based in Bengaluru, we offer a comprehensive range of Conveyor Repair Materials designed to deliver reliable, long-lasting, and efficient repair solutions for all types of conveyor belts.

Our product range includes: